Biohybrid Robotics

Robots grown from muscle cells only require chemical energy to function

From Bioinspiration to Biohybridization

Principles and mechanisms found in nature have inspired scientists to develop advanced artificial materials, including dynamic systems, in a biomimetic endeavor that embraces the use of soft, compliant materials. Over the last few decades, we constructed small-scale robots from soft materials, programmed them for different motion abilities, and let them undertake various tasks. As a result, soft technologies will expedite the evolution of devices that safely adapt to interactions with natural environments and humans.

However, conventional inanimate robotics cannot fully mimic living systems' structural and functional complexity, such as cells and tissues. Biological cells have an autonomous and adaptive nature, efficiently produce and use energy, duplicate and propagate, and are capable of various complex functions. As seen with the eyes of an engineer, cells are modular multifunctional units that can be assembled to form assemblies covering the micro-to-cm scale range (bottom-up tissue engineering). Due to their small single-unit size, cells offer a new approach to device miniaturization; their assembly ability opens perspectives for bio-hybrid robotics' applications and performances.

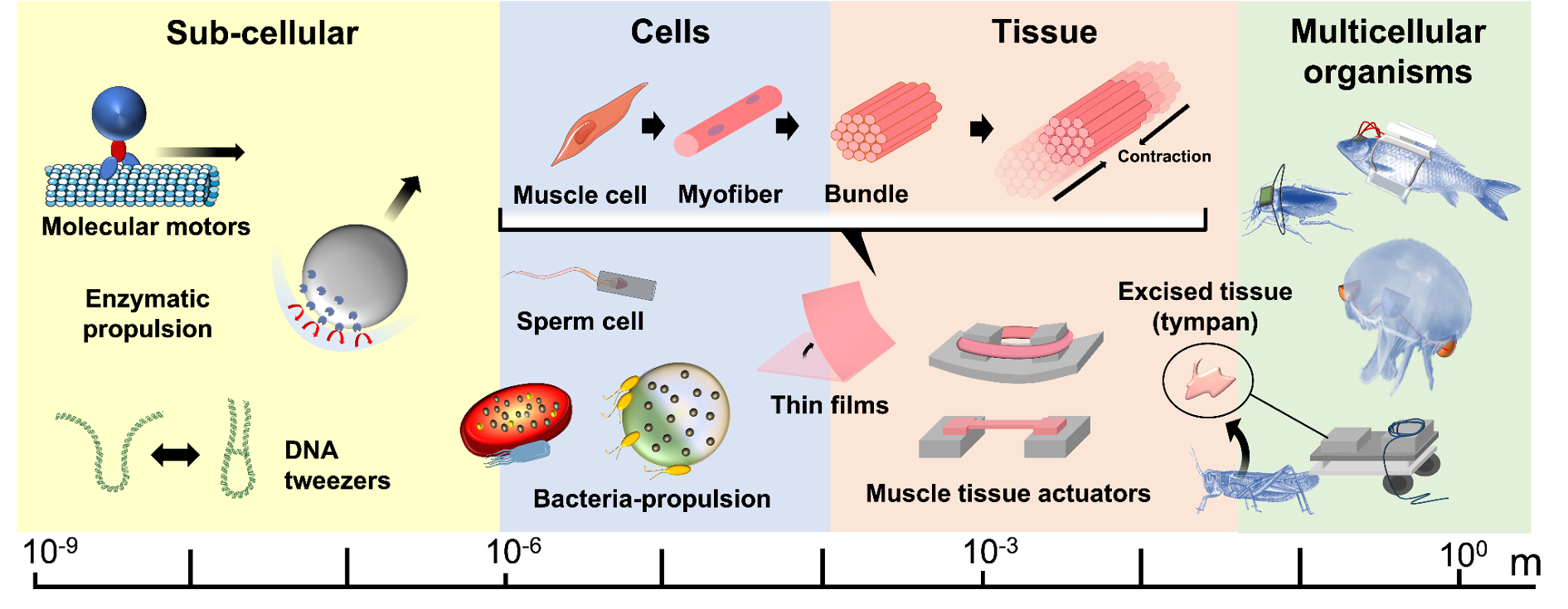

Multiscale bio-hybridization. Bio-actuation systems can be realized by exploiting dynamic molecular interactions, the catalytic activity of enzymes, motile bacteria cells, or micro/milli-scale functional muscle tissue constructs. Integrated tissues or animals into machines can lead to biological control of machines or artificial control of organisms. Filippi et al., PNAS, 2022. (external page https://www.pnas.org/doi/full/10.1073/pnas.2200741119)

Bio-hybrid Robotics: Frontier Robotics that Uses Living Materials to Achieve Motion

Robots arising from a combination of living systems (i.e., cells and tissues) and synthetic, soft materials are called ‘bio-hybrid robots’. Living materials hold promise for future, sustainable robotics in the fact they have intrinsic softness, higher environmental safety and compatibility, and more efficient energy conversion processes than traditional robots.

The biological modules used in bio-robotics can serve as sensors, power suppliers, or processors/controllers, but thus far they have been mostly applied as actuators. Bio-actuators use cells with specialized contractility to generate global deformation of structures. Contractile cells are typically muscle cells of skeletal muscle or cardiac type, which are extracted from animals and humans. In the last years, different cells, scaffolding materials, and control paradigms were combined to engineer bio-hybrid robots capable of various motion abilities (i.e., swimming, bending, rotating, crawling, etc.) and applicable to tissue modeling; drug loading, delivery and screening; fluid actuation; bioimaging; tissue repair; and object manipulation.

SRL’s Contribution to Bio-hybrid Robotics

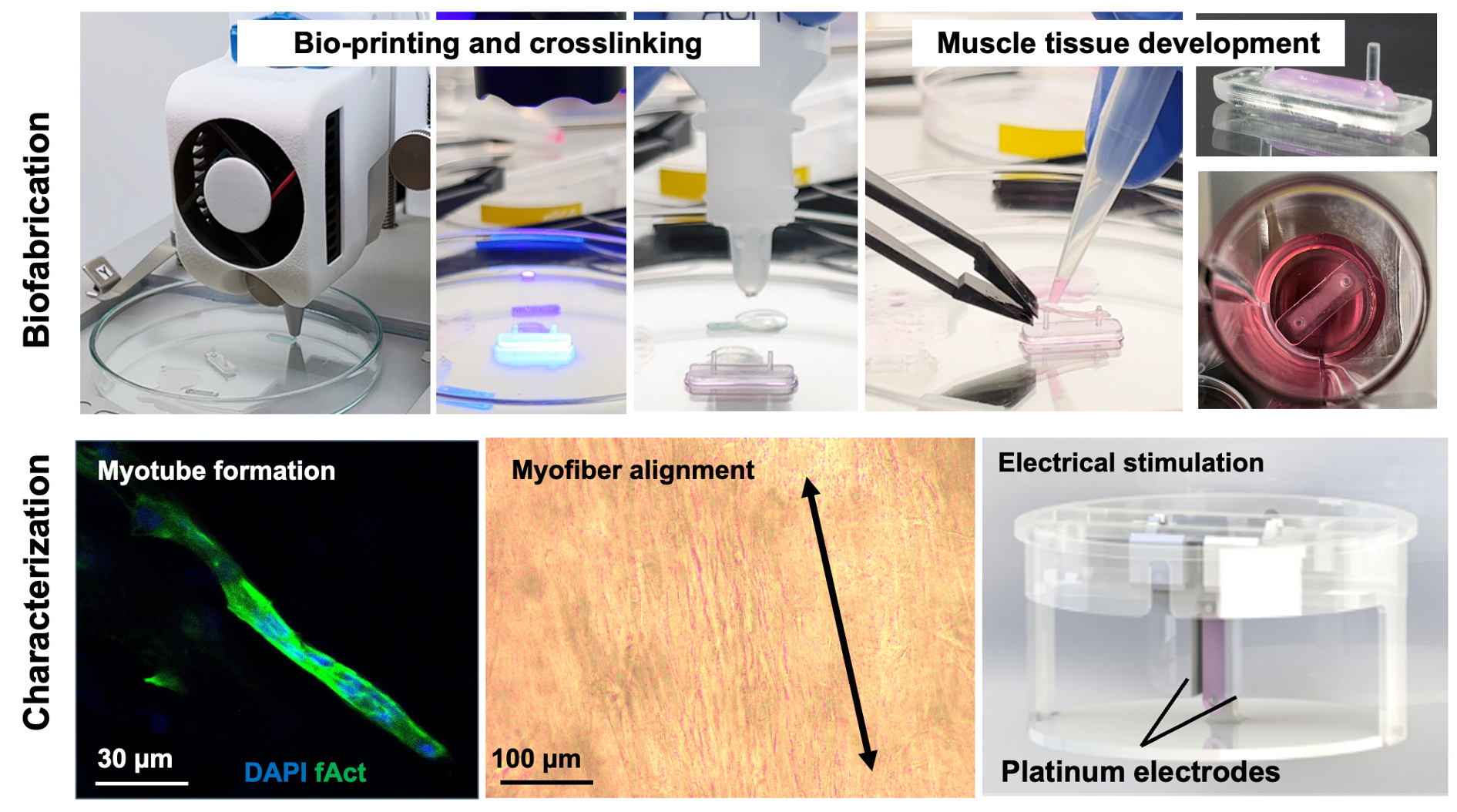

In our lab, we design, fabricate and study bio-hybrid robots to achieve controllable motion. We build our robots with various tissue engineering approaches, including conventional techniques (hydrogel casting; micro-molding) and light- or extrusion-based bioprinting. Biofabrication brings us to deal with material and biological sciences to generate novel tissue-based systems where cells can survive and develop into muscle tissues. We actuate our robots via electrical stimulation, which requires efforts on engineering setups and finding materials to deliver electrical cues to cells. We then study actuation via motion recording and apply it to solve specific tasks.

Biofabrication and characterization of contractile muscle in the Soft Robotics Lab. We use different approaches to fabricate skeletal or cardiac muscle tissue (including extrusion-based bioprinting, top). We develop the tissue in culture and then characterize it for its content in functional muscle structures (e.g., myotubes and myofibers). We apply electrical stimulation to actuate the muscle and realize bio-actuatable systems.

Our major research challenges are:

● scaling up engineered muscle tissues;

● controlling myofiber formation during biofabrication and tissue development;

● exploring tissue designs from biomimetic to biosynthetic forms for motion;

● integrating proprioception in muscle-based actuators;

● discovering and engineering materials for sustainable bio-hybrid robotics (e.g., non-mammalian species).

Related Works

M. Filippi, O. Yasa, R. D. Kamm, R. Raman, R. K. Katzschmann, "external page Will microfluidics enable functionally integrated biohybrid robots?" Proceedings of the National Academy of Sciences, 2022, 119 (35), e2200741119.

M. Filippi, T. Buchner, O. Yasa, S. Weirich, R. K. Katzschmann, "external page Microfluidic Tissue Engineering and Bio‐actuation." Advanced Materials, 2022, 34, 2108427.

M. Filippi, F. Garello, O. Yasa, J. Kasamkattil, A. Scherberich, R. K. Katzschmann, “external page Engineered Magnetic Nanocomposites to Modulate Cellular Function.” Small, 2022, 18 (9), 2104079.