Sinergia - Bioxolography

Bioxolography and machine learning to engineer skeletal muscle tissue for actuation

Engineered 3D skeletal muscle tissue is an important model for studying muscle physiology and disease, with applications in regenerative medicine, in vitro drug screening, bio-hybrid robotics, and cultured meat. Nevertheless, current muscle tissue models do not effectively reproduce the structural complexity and function of biological muscle.

This project aims at engineering 3D skeletal muscle tissue models that mimic cellular heterogeneity, architecture, and performance of native muscle.

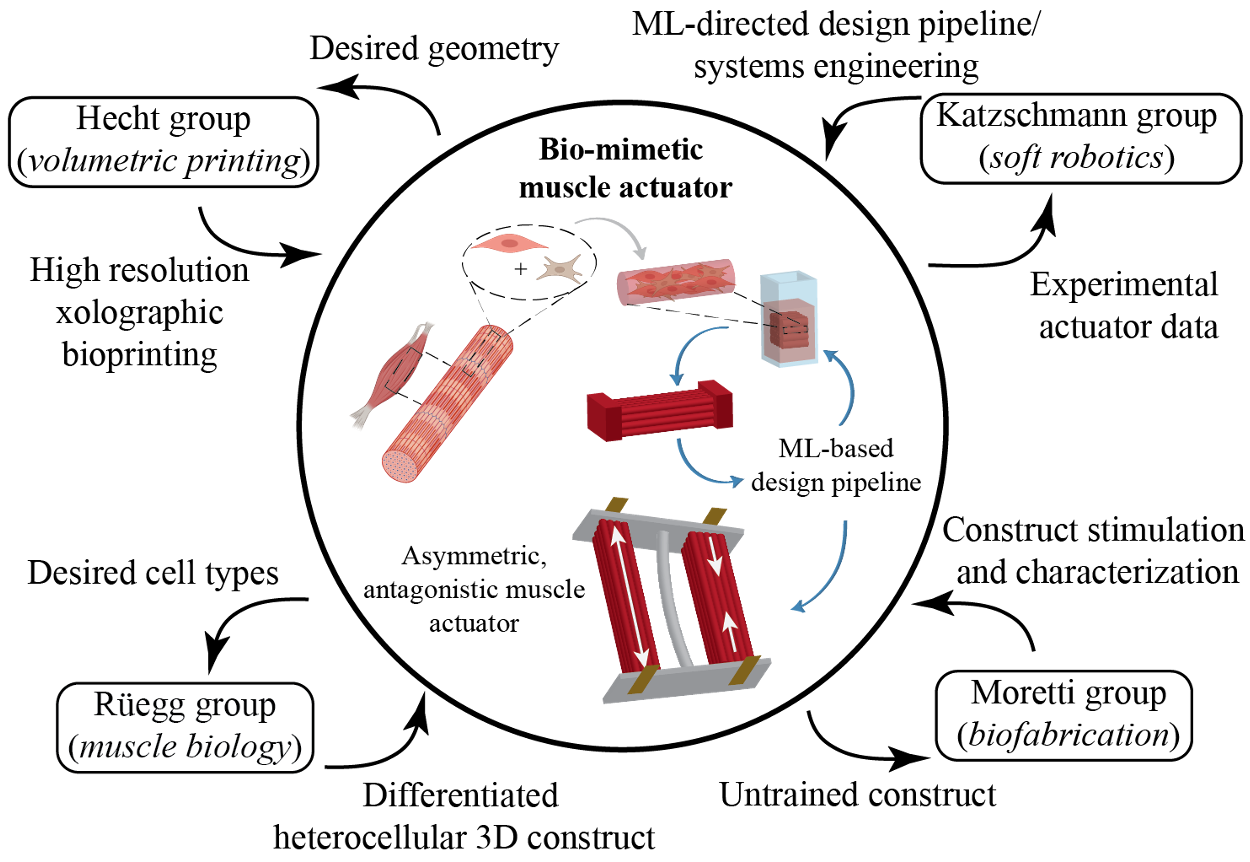

By gathering diverse experiences in both biological and non-biological manufacturing, our Sinergia Consortium will develop bio-hybrid systems that are actuated by engineered muscle tissue, and will study their motion response. To engineer such models, we will adopt machine learning-based predictive approaches to biofabrication and novel, high-resolution 3D printing techniques. Understanding and fabricating living tissue requires biological competence on the biomolecular, cellular, and whole tissue scales; integrating, streamlining and modeling the process requires in silico robotics expertise.

Our Sinergia project is driven by the wealth of capabilities and experience of the participating groups (Fig. 1), namely:

- Hecht group’s know-how in photochemistry and volumetric printing at Humboldt University in Berlin;

- Rüegg group’s expertise in the characterization of molecular, biochemical, and physiological pathways controlling muscle function at the Biozentrum of the University of Basel;

- Moretti group’s competence in musculoskeletal tissue biofabrication at the Regenerative Medicine Technologies (RMT) Lab at Ente Ospedaliero Cantonale (Bellinzona);

- Katzschmann group’s expertise in manufacturing and modeling soft robots at the Soft Robotics Lab at ETH Zurich.

Project Partners: xolo.

In this project, we will investigate the adoption of high-resolution light-based 3D printing to manufacture biological constructs with controlled cell orientation; study heterocellular populations (e.g., muscle cells with motor neurons or fibro-adipogenic progenitor cells) to generate more biomimetic skeletal muscle constructs; characterize the tissue maturation process of the engineered muscle tissues, and describe its biomechanics and the evoked contractile response; develop machine learning-based pipeline to guide the biofabrication and design of biological muscle actuators. Through this understanding, the project will culminate in the realization of centimeter-scale asymmetric, antagonistically actuated skeletal muscle constructs.

With this project, we first expect to accelerate and improve the design and fabrication of functional skeletal muscle tissue by providing an in-silico-to-in-vitro platform for 3D muscle construct design. Our work will provide insights into biofabrication, soft materials, 3D cell culture techniques, hetero-cellular models, bio-hybrid technologies, robotic design, and biophysical cell stimulation. We anticipate multidisciplinary advancements in tissue engineering, muscle physiopathology, 3D bioprinting, the development of new therapeutics, biological machine learning, bio-hybrid robotics, and engineering with living materials.